Super expanded metal(Materials)

Feature

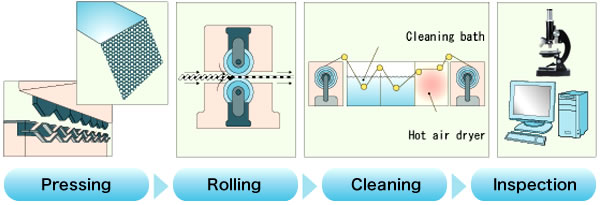

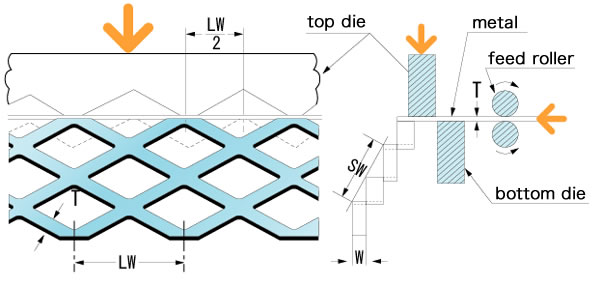

Super expanded metal is a mesh that is formed by cutting metallic foil and expanding it by 1/2 SW.

Super expanded metal is made in a high efficiency process, and its unique structure makes it extremely strong.

Super expanded metal is made in a high efficiency process, and its unique structure makes it extremely strong.

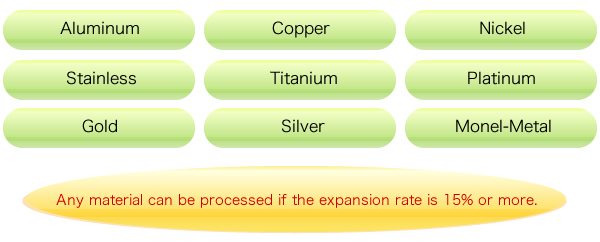

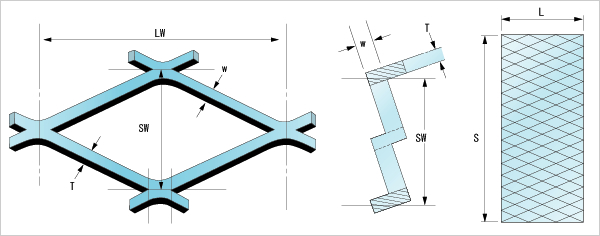

Metal Composition

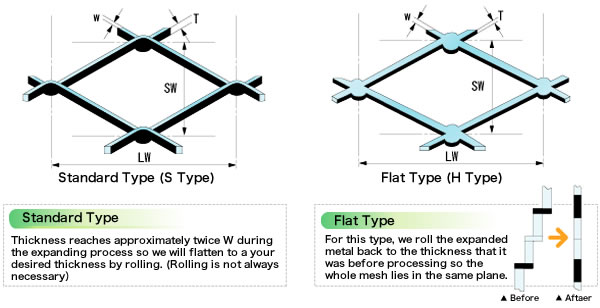

| SW:Center distance of the mesh (short direction) LW:Center distance of the mesh (long direction) W :Indent width T :Thickness of the material |

D:Thickness of the expanded metal S:Length of SW direction product L:Length of LW direction product |

Processing Options

1. Hoop processing

・The metal is wound around a paper or iron tube.

・Diameter of the tube is 76m/m

・Max 1000m/R depend on the number of the winds

・Diameter of the tube is 76m/m

・Max 1000m/R depend on the number of the winds

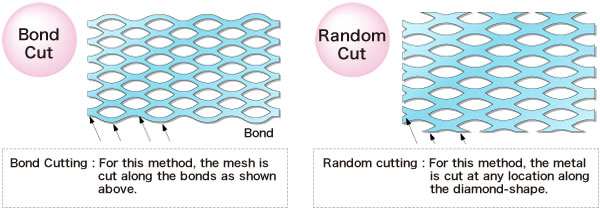

2. Cut processing

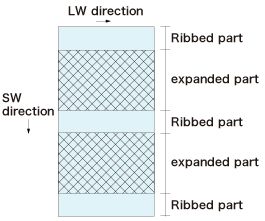

3. Expansion process with rib attached

We can produce to your specifications : We can change the ribbed and expanded part as requested.

Using our original technique, we can process metallic as thin as 30 microns.

This processing is possible for both standard and flat types.

It is possible to cut away and then wind the metal.

Secondaty Processing

1.Press processing >>> Stamp to your desired form.

2. Bend processing >>> Bend to your desired form by using a bending machine.

3. Cut processing >>> Cut to desired size.

4. Slit processing >>> Slit to desired width and length.

5. Spot welding >>> Spot weld to the desired form.

Basic Equations

Expansion rate

Ratio of expansion (expanded from material of 1m)

Expansion rate=SW/2/W

Expansion rate=SW/2/W

Unit weight of expanded metal

Weight for the expanded metallic foil

Unit weight of the expanded metal=weight of the metallic foil per 1m/expansion rate

Unit weight of the expanded metal=weight of the metallic foil per 1m/expansion rate

Aperture rate

Space rate of the metallic foil and expanded metal

Aperture rate=1-(unit weight of expanded metal/unit weight of metallic foil)

Aperture rate=1-(unit weight of expanded metal/unit weight of metallic foil)

Possible Uses

Energy related

Lithium primary battery, Lithium ion battery, Button nickel-cadmium battery, Air battery, Lithium polymer battery, Electrolysis double layer condenser, Fuel cell

Sport related

Golf club shafts, Tennis and badminton racket frames, Fishing rodsComputer related

EMI shieldsPrecision equipment related

Various medical equipment, Acoustic equipment, Filter, AutomobileOthers

Ornaments, Gasket, Covers, and other miscellaneous goodsProduction Specification

(Unit:m/m)

| PNO | SW | LW | Indent width range W |

Range of board thickness T |

Maximum processing breadth | |

| AL・Cu | SUS・Ti・Ni | |||||

| 1 | 0.5 | 1.0 | 0.05〜0.2 | 0.03〜0.1 | 300 | 300 |

| 2 | 0.9 | 1.0 | 0.08〜0.3 |

0.05〜0.2 | 500 | For Ni 300 |

| 3 | 1.1 | 1.4 | 0.08〜0.3 | 0.05〜0.3 | 300 | For Ni 300 |

| 4 | 0.7 | 1.3 | 0.05〜0.3 | 0.03〜0.15 | 650 | 650 |

| 5 | 0.8 | 1.5 | 0.05〜0.3 | 0.03〜0.15 | 650 | 650 |

| 6 | 1.0 | 2.0 | 0.05〜0.5 | 0.03〜0.3 | 650 | 650 |

| 7 | 1.2 | 2.5 | 0.05〜0.6 | 0.03〜0.4 | 650 | 650 |

| 8 | 2.0 | 2.5 | 0.05〜0.8 | 0.03〜0.3 | 650 | 650 |

| 9 | 1.0 | 3.0 | 0.05〜0.8 | 0.03〜0.3 | 650 | 650 |

| 10 | 1.5 | 3.0 | 0.05〜0.8 | 0.03〜0.4 | 650 | 650 |

| 11 | 2.0 | 3.0 | 0.05〜1.0 | 0.03〜0.4 | 650 | 650 |

| 12 | 2.5 | 3.0 | 0.05〜1.0 | 0.03〜0.5 | 650 | 650 |

| 13 | 2.0 | 4.0 | 0.05〜1.0 | 0.03〜0.6 | 650 | 650 |

| 14 | 3.0 | 4.5 | 0.05〜1.0 | 0.03〜0.6 | 650 | 650 |

| 15 | 2.0 | 5.0 | 0.05〜1.0 | 0.03〜0.8 | 650 | 650 |

| 16 | 2.5 | 5.0 | 0.05〜1.0 | 0.03〜0.8 | 650 | 650 |

| 17 | 1.7 | 6.0 | 0.05〜1.0 | 0.03〜0.8 | 650 | 650 |

| 18 | 2.0 | 6.0 | 0.05〜1.0 | 0.03〜0.8 | 650 | 650 |

| 19 | 3.0 | 6.0 | 0.05〜1.5 |

0.03〜0.8 | 650 | 650 |

| 20 | 3.4 | 6.0 | 0.05〜1.5 | 0.03〜0.8 | 650 | 650 |

| 21 | 5.0 | 6.0 | 0.05〜1.5 | 0.03〜0.8 | 650 | For Ni 500 |

| 22 | 4.0 | 8.0 | 0.05〜1.5 | 0.03〜0.8 | 650 | 650 |

| 23 | 4.5 | 8.0 | 0.05〜1.5 | 0.03〜0.8 | 650 | 650 |

| 24 | 2.2 | 10.0 | 0.05〜1.0 | 0.03〜1.0 | 650 | 650 |

| 25 | 5.0 | 10.0 | 0.05〜1.5 | 0.03〜.10 | 650 | 650 |

| 26 | 7.0 | 14.0 | 0.05〜1.5 | 0.03〜1.0 | 650 | 650 |

| 27 | ||||||

| 28 | ||||||

| 29 | ||||||

| 30 | ||||||

※It is possible to produce to specifications not listed above. Please inquire.